It is one of the most modern solution for the problem of extracting milling products from the deposit bins. The efficacy criterion of high frequency vibration, the semplicity of construction and security in using it make this system the most rational solution of the problem.

The functioning of the machine is based on the vibrating movement, the simplest one to get to come out a product from a container.

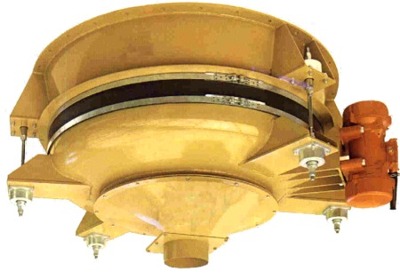

The impressed vibration from a vibrating motor to the suspended hopper provoke the material dischargement from the deposit cellules. The product slides on the convex plate placed in the middle of the extractor and it goes down from a wide circular pheripheral crak towards the outlet.

The efficiency of the criterion of this machine assures a uniform extraction for milling products and products with difficult sliding. All parts susceptible of upkeep are placed on exterior side of the machine so it is easy to replace one of it even if the cellules are full of product.Upkeep is the simple control of the rubber parts.

The machine is composed by two elestically connected hoppers; the first is superior, conical-cut and it is fixed to the bottom of silos, the other is convex and suspended at the first by means of strong tie which are fastened to special elastic pillow to allow the vibration impressed by a vibrating motor.

At the inside of the machine a big circular structure, purposely shaped, keeps the outlet free so the product slides towards periphery allowing an easy and continuous estraction flux.

Each part of the extractor is shaped in such a way to resist the high pressions on the bottom of the deposit cellules.