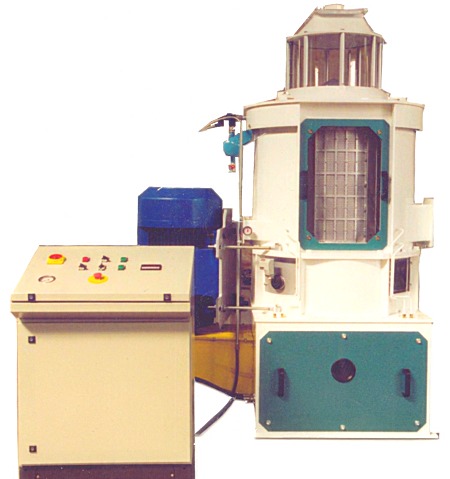

An innovative concept in the milling technology has been reached by designing and manufacturing this machine called scourer-optimiser that offers numerous technical, economical and qualitative advantages.

Technical advantages

It gives the possibility to reduce the number of milling and cleaning machines but preserving their power. Moreover, the bran particle size does not need extra machine to be reduced.

Economic benefits

They derive from the lowest number of machines to be installed (in grinding and cleaning section). Therefore a better performances of the system should mean less up-keep costs and less electric power for milling. Moreover it could be possible to put the so-called “optimiser”in existing milling plant improving unit capacity about 30% with the same machines.

Qualitative benefits

Can be reached by milling a corn whose bran parts have already been removed; in this way the miller has a less risks to break the bran.

This procedure allows to get superfine flours with a minor part of bran and black parts and have therefore a more homogeneous bran particle size.Such a characteristic is the result of milling the treated corn with this new system, and at the same time, remarkable advantages for pasta factories, since during the kneading pase it allows forstly to use superfine flour with compact particle size and secondly to have a more homogeneous hydration which will improve the final pasta shape.

Grinding a corn which has been cleaned by the optimiser it allows to have a more constant grinding with more control on ashes with improved yield and degree of refinement of semolina produced.

Thanks to it, the intervention of control and calibration of the machines are reduced. Indeed, for each intervention it is necessary a control on ashes, causing long waiting time.

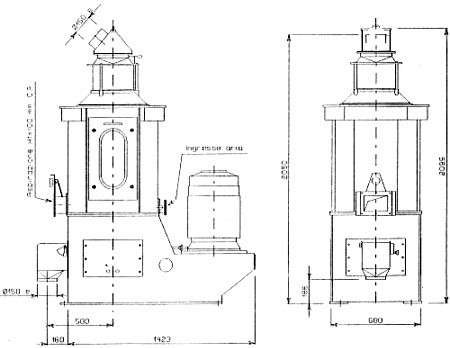

Vertical Scourer

It is used to take off the bran layer from wheat, barley and some other cereal, without spoiling the grain itself.

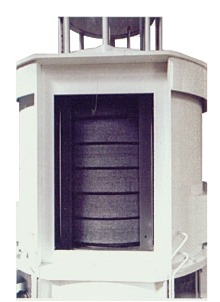

The cereal to debran is put in the machine by the feed hopper. At its inside the cereal is distributed on the whole external surface of the millstone.The circular movement, the roughness of the millstones, the peripheral velocity, the screen and the adjusting distanceon outlet, produce an abrasion/friction on the external part of the grain. It gets down through the outlet below without its external layer.

A fundamental role is played by the aspirating air at the inside of the machine since it provides both the evacuation of the bran layers and the screen cleaning.

So, the debranned cereal is sorted out in the two outlets standing below. The adjusting on outlet determinates the capacity and it is controlled both manually and automatically .