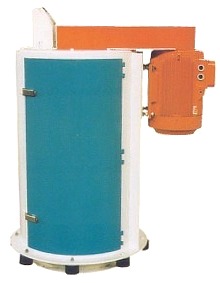

In dry degerming process, the vertical degermination breaks the kernels to enucleate the germ with minimum milling products which are automatically separated by the stator grill.

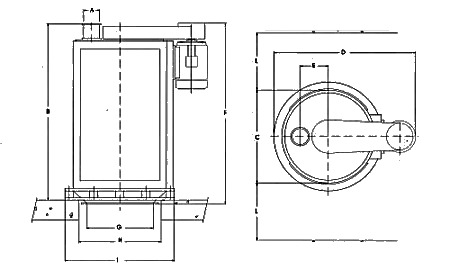

The maize enters from the upper section and it is uniformly distributed on stator circumference thanks to a rotation disk.

The advance of this system is to have a better grains breaking and a lower consumption of the perforated cover.

While the maize runs across the vertical cylinder length, it is exposed to a series of crashes and rubbings which detach, without damaging the germ, most of the bran and the white flour with a lot of fat which adhere to the kernel glassy area.It is possible to govern the breaking into pieces action, by varying the distance between cover and beaters paddles: the shortest is the distance, the highest is the breaking effect and self-friction.

The broken product with big granulation goes from up to down, the thin one is expelled through the cover holes. The products are gathered in the hopper placed below. It has a particular shape in order to divide the coming out covers and the holes parts.